Isixazululo se-Ceramic coil vape

I-Silicore technical iyinkundla ye-atomization esekelwe ekutholeni ibhalansi phakathi kwamandla, ukushisa nokugeleza.

Indlela Yomoya:

Umzila womoya uthinta ukuvuza kwamafutha, i-condensate, njll. Uma indlela yokuphefumula ibushelelezi, futhi intuthu ye-athomu inqwabelanisa futhi ihlale endleleni yomoya, izofiphala; umzila womoya awunaso isakhiwo sokungenisa umoya se-buffer. Ngokusetshenziswa kwe-e-liquid, umoya endaweni yokugcina uwoyela uyakhula, wenze umehluko wengcindezi, okumele kuvuze uwoyela.

I-Oilway:

Amaphaseji kawoyela aklanywe kabi azoholela ekukhathaleni nasekwakhekeni kwekhabhoni. Uma umzila kawoyela uvalwe ngamabhamuza omoya, ngisho nomongo we-atomizer oshesha kakhulu uzokwenziwa ikhabhoni.

Ukuze kuzuzwe ukunambitheka okwedlulele, izinga lokushisa elifanele le-atomization lamafutha omusi liyisidingo. Ukufanisa izakhiwo ze-thermodynamic namandla we-ceramic atomizer cores kubalulekile.

Uhlobo lwe-E-liquid:

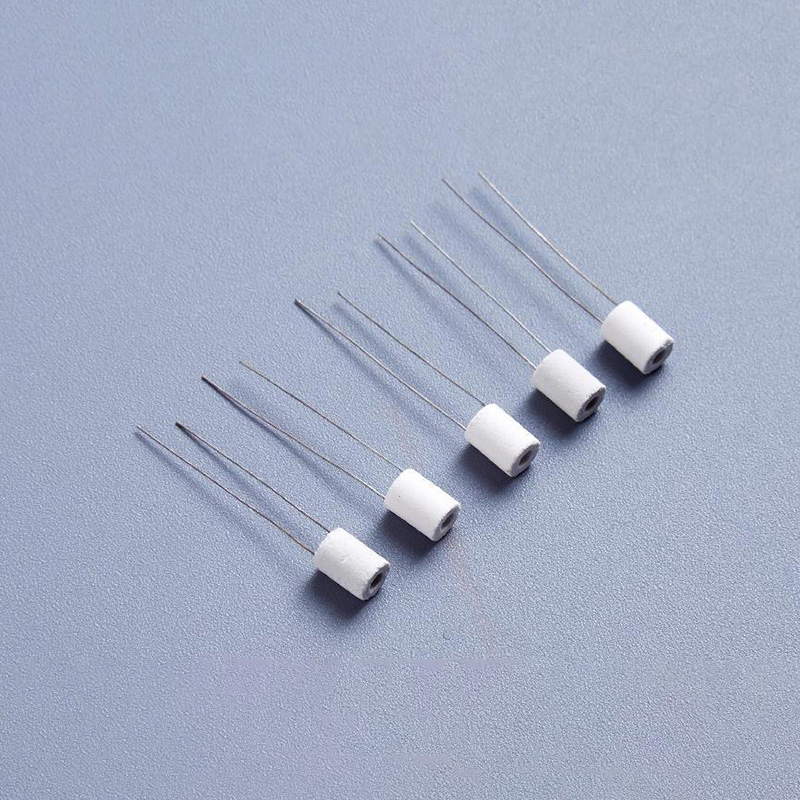

Ugwayi olahlwayo, i-e-liquid emanzi futhi emnandi kakhulu idinga ukukhetha ikhoyili ye-ceramic yezinwele eziqondile, ngoba indlela yomoya mfushane.

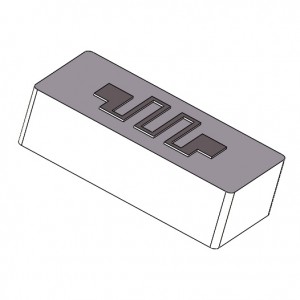

Ukuze uthole ukuguqulwa kwezinhlamvu kanye ne-e-liquid ethambile futhi entsha, udinga ukukhetha ikhoyili ye-ceramic eyisicaba.

Amandla:

<7W khetha ikhoyili ye-ceramic yefilimu ewugqinsi, ethi ngokuqhuma okunamandla, idinga kuphela amandla aphansi ukuze ifinyelele izinga lokushisa elifanele le-athomu;

>7.5W khetha ikhoyili ye-ceramic ye-SMD, edinga amandla aphezulu ukuze ifinyelele izinga lokushisa elifunekayo le-atomization.

I-viscosity yoketshezi lukagwayi:

I-viscosity ye-e-liquid ithinta ngokuqondile izinga lokushisa kwe-atomization. Ngemuva kokunquma i-viscosity ye-e-liquid, ikhoyili ye-ceramic iyisinqumo esingcono kakhulu. Isivinini sokuqhuba uwoyela isivinini sokuqhuba uwoyela esidingekayo ukuze kufinyelelwe izinga lokushisa elifanele le-atomization. Hhayi ngokushesha kakhulu, hhayi kancane kakhulu.