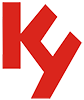

I-Zirconia Rod Ceramic Heating Element ye-DC voltage E-cigarette device

Ukwethulwa kwe-Keycore Ⅱ (HTCC ZCH) yesici sokushisa esibaselwe ngokushisa okuphezulu kwe-zirconia

Izinga lokushisa likhuphuka ngokushesha

Idizayini eyize yangaphakathi

Izinto ze-Zironia

I-Electrode yezinga eliphezulu lokushisa kwesiliva

Amandla okugoba angafinyelela ku-15KG. Iheater yethiphu ye-zirconia enkulu ngokuphindwe kathathu (ye-IQOS) futhi inkulu ngokuphindwe ngo-1.5 kunethiphu ye-alumina heater.

Ukusetshenziswa kwamandla okuphansi, okuphansi ngo-29% kune-Keycore I

Ishisa ngokushesha, uma iqhathaniswa ne-alumina Keycore I, ishesha imizuzwana engu-7.5 ifike ku-350 ℃, ukushisa ngokushesha kukhuphuke izikhathi ezingu-1.7

Izinga lokushisa le-Flange liphansi, amasekhondi angu-30 ngo-350degrees, izinga lokushisa le-flange lingaphansi kuka-100 ℃.

| Ububanzi | 2.15±0.1mm |

| Ubude | 19±0.2mm |

| Ukumelana Nokushisa | (0.6-1.5)±0.1Ω |

| Ukushisisa i-TCR | 1500±200ppm/℃ |

| Ukumelana Nezinzwa | (11-14.5)±0.1Ω |

| Inzwa ye-TCR | 3500±150ppm/℃ |

| I-Lead Soldering Melana Nokushisa | ≤100℃ |

| lead tensile force | (≥1kg) |

Izimo zokuhlola: i-voltage yokusebenza izokwenza izinga lokushisa lomkhiqizo lifinyelele kuma-degree angu-350, bese lihlola izinga lokushisa le-flange ngemva kwama-30S wokuzinza.

Izinga lokushisa le-flange le-Keycore II (HTCC ZCH) liphansi uma lisebenza. Izinga lokushisa le-flange ngemva kwemizuzwana engu-30 yokugcina izinga lokushisa elingu-350 ℃ ku-voltage yokusebenza engu-3.7v alikho ngaphezu kuka-100 ℃, kanti le-Keycore I licishe libe ngu-210 ℃ ngaphansi kwezimo ezifanayo.

Izifudumezi ze-Ceramic zinezici ezilandelayo:

Ukuzinza kwezinga lokushisa eliphezulu: Izinto zobumba zinokuzinza okuhle kwezinga lokushisa eliphezulu futhi zingakwazi ukugcina ukusebenza okuzinzile ezindaweni ezishisayo, ngakho zifanelekela izikhathi zokushisa eziphezulu.

Ukumelana nokugqwala: Izinto zobumba zinokumelana nokugqwala okuqinile, zingasebenza kweminye imithombo yezindaba ezonakalisayo, futhi zilungele izidingo zokushisisa ezindaweni ezikhethekile.

Ukusebenza kwe-insulation: Izinto ze-Ceramic zinezakhiwo ezinhle zokuvikela, ezingavimbela ngokuphumelelayo ukuvuza kwamanje futhi zithuthukise ukusebenza kokuphepha kwe-heater.

Ukushisisa Okufanayo: Izifudumezi ze-Ceramic zingafinyelela umphumela wokushisa ofanayo ngokuqhathaniswa, zigweme ukushisisa ngokweqile kwendawo noma ukupholisa kancane, futhi zifanele izikhathi ezidinga ukushisa okuphezulu okufanayo.

Ukonga amandla nokuvikelwa kwemvelo: Izifudumezi ze-Ceramic zivame ukusebenza kahle kakhulu futhi zingaguqula amandla kagesi abe amandla okushisa ngokusebenza kahle okuphezulu, ngaleyo ndlela ehlise ukusetshenziswa kwamandla futhi ahlangabezane nezidingo zokonga amandla nokuvikelwa kwemvelo.

Impilo ende: Ngenxa yokuthi izinto ze-ceramic zinokumelana okuhle nokuqina, izifudumezi ze-ceramic zivame ukuba nempilo ende yesevisi.

Ngokuvamile, ama-heaters e-ceramic anezici zokuzinza kokushisa okuphezulu, ukumelana nokugqwala, ukufakwa kwe-insulation, ukushisa okufanayo, ukonga amandla nokuvikelwa kwemvelo, nokuphila isikhathi eside, futhi kufanelekile ezinhlobonhlobo zezikhathi zokushisa zezimboni nezasendlini.