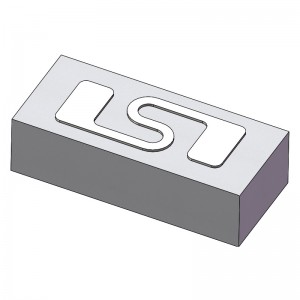

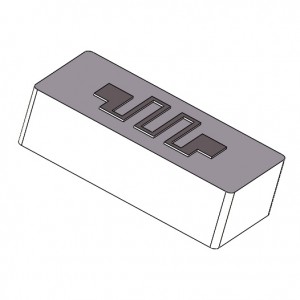

I-ZTA Rod Ceramic Heating Element ye-DC voltage E-cigarette device

Ukwethulwa kwe-Keycore III (ZTA)

Idizayini eyize yangaphakathi

Izinto ze-Zironia

I-Electrode yezinga eliphezulu lokushisa kwesiliva

Amandla okugoba angafinyelela ku-15KG. Iheater yethiphu ye-zirconia enkulu ngokuphindwe kathathu (ye-IQOS) futhi inkulu ngokuphindwe ngo-1.5 kunethiphu ye-alumina heater.

Ukusetshenziswa kwamandla okuphansi, okuphansi ngo-29% kune-Keycore I

Ishisa ngokushesha, uma iqhathaniswa ne-alumina Keycore I, ishesha imizuzwana engu-7.5 ifike ku-350 ℃, ukushisa ngokushesha kukhuphuke izikhathi ezingu-1.7

Izinga lokushisa le-Flange liphansi, amasekhondi angu-30 ngo-350degrees, izinga lokushisa le-flange lingaphansi kuka-100 ℃.

| Ububanzi | 2.15±0.1mm |

| Ubude | 19±0.2mm |

| Ukumelana Nokushisa | (0.6-1.5)±0.1Ω |

| Ukushisisa i-TCR | 1500±200ppm/℃ |

| Ukumelana Nezinzwa | (11-14.5)±0.1Ω |

| Inzwa ye-TCR | 3500±150ppm/℃ |

| I-Lead Soldering Melana Nokushisa | ≤100℃ |

| lead tensile force | (≥1kg) |

Izimo zokuhlola: i-voltage yokusebenza izokwenza izinga lokushisa lomkhiqizo lifinyelele kuma-degree angu-350, bese lihlola izinga lokushisa le-flange ngemva kwama-30S wokuzinza.

Izinga lokushisa le-flange le-Keycore II (HTCC ZCH) liphansi uma lisebenza. Izinga lokushisa le-flange ngemva kwemizuzwana engu-30 yokugcina izinga lokushisa elingu-350 ℃ ku-voltage yokusebenza engu-3.7v alikho ngaphezu kuka-100 ℃, kanti le-Keycore I licishe libe ngu-210 ℃ ngaphansi kwezimo ezifanayo.

Ama-heaters e-Ceramic asetshenziswa kabanzi emikhakheni eminingi ngenxa yezakhiwo zawo ezikhethekile kanye nezinzuzo, kufaka phakathi kodwa kungagcini kulezi zici ezilandelayo:

Ukushisa kwemboni: Izifudumezi ze-Ceramic zivame ukusetshenziswa ekushiseni imishini ekukhiqizeni izimboni, njengokushisa kwepulasitiki yokubumba, ukufudumeza kwerabha, ukushisa kwengilazi, ukushisa ukudla nezinye izinkambu.

Imboni yamakhemikhali: Ngenxa yokumelana nokugqwala kwezinto zobumba, izifudumezi ze-ceramic zivame ukusetshenziselwa ukushisisa imidiya egqwalayo embonini yamakhemikhali, njengokushisisa izixazululo ze-asidi ne-alkali.

Imishini yezokwelapha: Ama-heaters e-Ceramic asetshenziswa kabanzi emkhakheni wemishini yezokwelapha, njengokufudumeza nokubulala amagciwane emishini yezokwelapha.

Izinto zasendlini: Izifudumezi ze-Ceramic nazo zivame ukusetshenziswa ezintweni zasendlini, njengamaketela kagesi, izinkomishi zikagesi, izingubo zokulala zikagesi, njll.

Inkambu yezimoto: Izishisi ze-Ceramic nazo zisetshenziswa emkhakheni wezimoto, njengokufudumeza kwesihlalo semoto, ukushisa kwenjini, njll.

Eminye imikhakha: Izifudumezi ze-Ceramic nazo zisetshenziselwa i-aerospace, ezempi, i-electronics, i-semiconductor nezinye izinkambu ukuze kuhlangatshezwane nezidingo zokushisa ezindaweni ezihlukahlukene ezikhethekile.

Ngokuvamile, ama-heaters e-ceramic asetshenziswa kabanzi ekukhiqizeni izimboni, imboni yamakhemikhali, ukwelashwa, izinto zasendlini, izimoto kanye nezinye izinkambu, futhi izakhiwo zabo ezikhethekile zibenza bafanelekele izidingo eziningi zokushisa ezithile.